Ukuphumelela noma ukwehluleka kokucutshungulwa kwepulasitiki kuncike kakhulu emphumeleni wokwakhiwa kwesikhunta kanye nekhwalithi yokukhiqiza isikhunta, futhi ukwakheka kwesikhunta sepulasitiki kusekelwe ekwakhiweni okufanele kwemikhiqizo yepulasitiki.

Izakhi zesakhiwo okufanele zicatshangelwe ekwakhiweni kwesikhunta sepulasitiki zifaka:

① Indawo ehlukanisayo, okungukuthi, indawo ethintana nayo phakathi kwentombazane efayo neyeduna lapho kufa ivaliwe.Ukukhethwa kwendawo kanye nesimo sawo kuthintwa yizici ezifana nokuma nokubukeka komkhiqizo, ukushuba kodonga, indlela yokwenza, ubuchwepheshe bangemva kokucubungula, uhlobo lwesikhunta kanye nesakhiwo, indlela yokudiliza kanye nesakhiwo somshini wokubumba.

② Izingxenye zesakhiwo, okungukuthi ibhulokhi eshelelayo, ngaphezulu etshekile, ibhulokhi ephezulu eqondile, njll. yokufa okuyinkimbinkimbi.Ukuklanywa kwezingxenye zesakhiwo kubaluleke kakhulu, okuhlobene nempilo yesevisi, umjikelezo wokucubungula, izindleko kanye nekhwalithi yomkhiqizo wefa.Ngakho-ke, idizayini yesakhiwo esiyinkimbinkimbi se-die core idinga ikhono eliphezulu elibanzi lomklami, futhi iphishekela uhlelo lokuklama olulula, oluhlala isikhathi eside futhi olunomnotho kakhulu ngangokunokwenzeka.

③ Ukunemba kokufa, okungukuthi ukugwema ikhadi, ukuma okuhle, iposi lomhlahlandlela, iphinikhodi yokubeka, njll. Uhlelo lokuma luhlobene nekhwalithi yokubukeka kwemikhiqizo, ikhwalithi yesikhunta kanye nempilo yesevisi.Izindlela ezihlukene zokumisa zikhethwa ngokwezakhiwo zesikhunta ezihlukene.Ukulawula ukunemba kokuma ngokuyinhloko kuncike ekucutshungulweni, futhi ukuma kwesikhunta sangaphakathi kucatshangelwa kakhulu umklami ukuze adizayine indlela enengqondo nelula yokulungisa indlela yokuma.

② Uhlelo lokungena, okungukuthi, umzila wokuphakela osuka kumbobo womshini wokubumba umjovo ukuya endaweni yokubumba, uhlanganisa umzila omkhulu wokugeleza, umzila we-shunt, isango kanye nomgodi wezinto ezibandayo.Ikakhulukazi, ukukhethwa kwesikhundla sesango kufanele kube kulungele ukugcwalisa isikhunta sesikhunta ngepulasitiki encibilikisiwe ngaphansi kwesimo esihle sokugeleza, futhi umgijimi oqinile kanye nezinto ezibandayo zesango ezixhunywe kumkhiqizo kulula ukukhishwa esikhunjini futhi zisuswe ngesikhathi sokuvula isikhunta ( ngaphandle kwesikhunta somgijimi oshisayo).

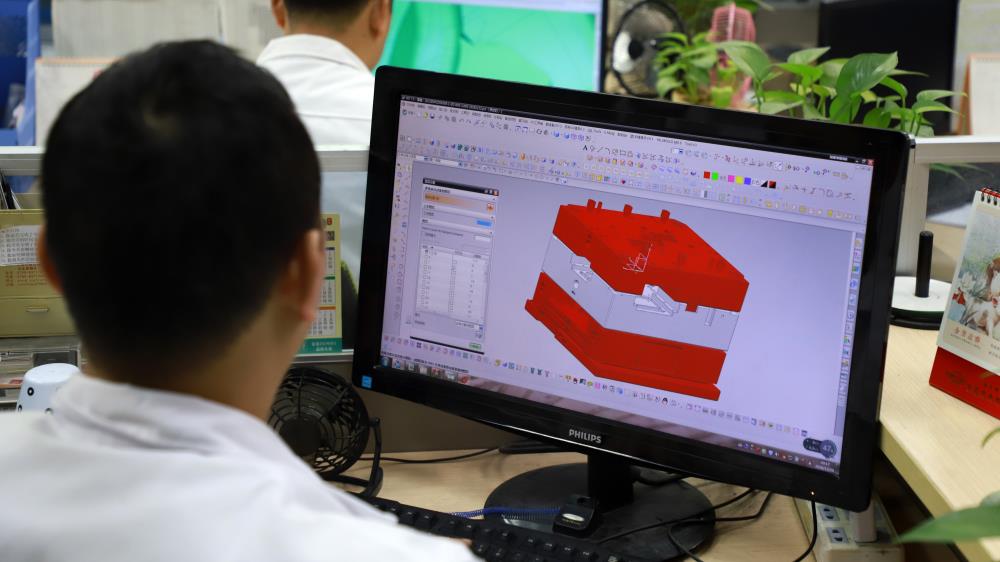

③ Ukuncipha kwepulasitiki nezici ezihlukahlukene ezithinta ukunemba kobukhulu bemikhiqizo, njengokukhiqiza isikhunta namaphutha omhlangano, ukuguga kwesikhunta nokunye.Ngaphezu kwalokho, ukufaniswa kwenqubo kanye nemingcele yesakhiwo somshini wokubumba kufanele futhi kucatshangelwe lapho uklama isikhunta sokucindezela kanye nesikhunta somjovo.Ubuchwepheshe bokuklama okusizwa ngekhompyutha busetshenziswe kabanzi ekwakhiweni kwesikhunta sepulasitiki.

Iyini idizayini yesistimu yokukhipha isikhunta sepulasitiki?

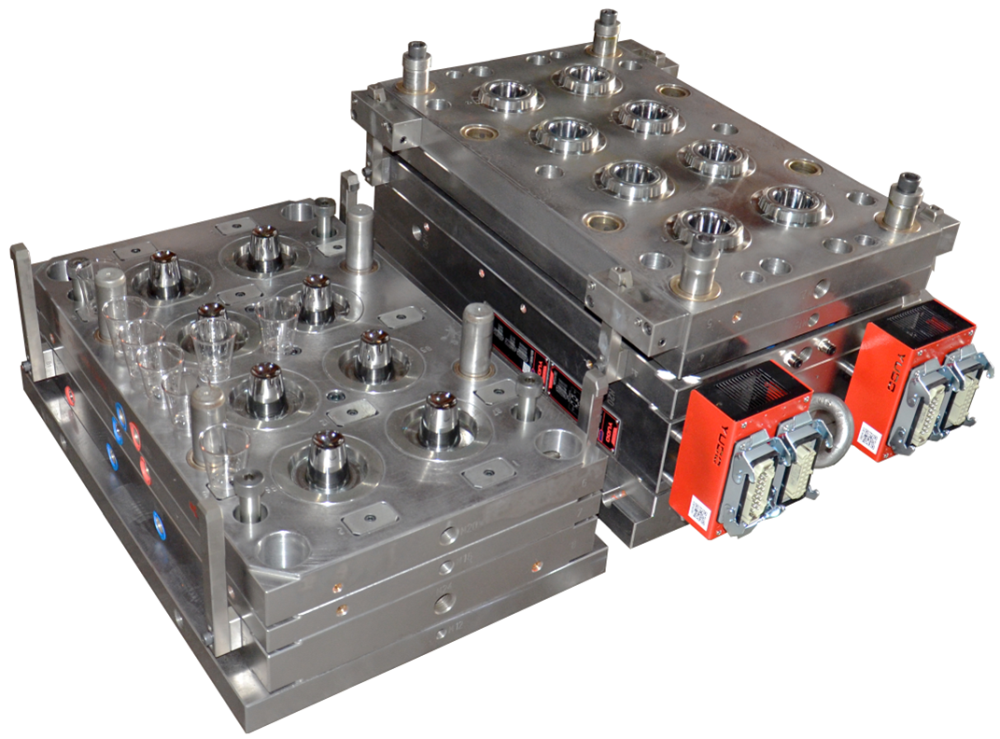

Isikhunta sokujova siyingxenye ebalulekile yokubumba umjovo.Sethule izimiso zokuklama umthamo we-cavity, indawo yesango, umgijimi oshisayo, umdwebo womhlangano kanye nokukhethwa kwempahla yokubunjwa komjovo.Namuhla sizoqhubeka nokwethula ukwakheka kwesistimu yokukhipha umjovo wepulasitiki.

Ngaphezu komoya wangempela osemgodini, igesi engaphakathi nayo iqukethe amagesi aguquguqukayo aphansi akhiqizwa ukushisisa noma ukuphulukiswa kwezinto zokubumba umjovo.Kuyadingeka ukucabangela ukukhishwa okulandelanayo kwalawa magesi.Ngokuvamile, ngesikhunta esinesakhiwo esiyinkimbinkimbi, kunzima ukulinganisa indawo enembile yokukhiya umoya kusengaphambili.Ngakho-ke, ngokuvamile kuyadingeka ukucacisa indawo yayo ngokusebenzisa ukuhlolwa kokufa, bese uvula i-slot yokukhipha.I-exhaust slot ngokuvamile ivulwa lapho u-Z ugcwele khona.

Imodi yokukhipha i-exhaust ukuvula i-slot yokukhipha umoya ngokusebenzisa i-clearance ehambisanayo yezingxenye zokufa.

Ukubunjwa kwezingxenye ezibunjiwe zomjovo kudinga ukucishwa, futhi ukudilizwa kwezingxenye ezibunjiwe zomjovo kudinga ukukhathala.Ezingxenyeni zokubumba umjovo wegobolondo elijulile, ngemva kokubunjwa komjovo, igesi engaphakathi iyaphephuka.Enqubweni yokudiliza, kwakhiwa i-vacuum phakathi kokubukeka kwezingxenye zepulasitiki nokubukeka kwengqikithi, okunzima ukuyiqeda.Uma demoulding ngempoqo, izingxenye umjovo olubunjiwe kulula deform noma umonakalo.Ngakho-ke, kuyadingeka ukwethula umoya, okungukuthi, phakathi komjovo obunjiwe ingxenye kanye nomgogodla, ukuze ingxenye ebunjiwe yomjovo wepulasitiki ingadilizwa kahle.Ngaso leso sikhathi, ama-grooves amaningana angajulile acutshungulwa endaweni ehlukanisayo ukuze kube lula ukuphuma.

1. Isifanekiso se-cavity kanye nomgogodla sidinga ukusebenzisa ibhulokhi yokuma eyi-conical noma ibhlokhi yokuma enembile.Umhlahlandlela ufakwe ezinhlangothini ezine noma eduze kwesikhunta.

2. Indawo ethintwayo phakathi kwepuleti lesisekelo sesikhunta kanye nenduku yokusetha kabusha idinga ukusebenzisa iphedi eliyisicaba noma iphedi eliyindilinga ukuze kugwenywe ukulimaza ipuleti.

3. Ingxenye enezimbobo yesitimela somhlahlandlela izothambekela ngaphezu kwamadigri angu-2 ukugwema ama-burrs nama-burrs.Ingxenye enezimbobo akufanele ibe yesakhiwo esincanyana.

4. Ukuze ugweme ukubola emikhiqizweni ebunjiwe yomjovo, ububanzi be-stiffener kufanele bube ngaphansi kuka-50% wogqinsi lwendawo ebukekayo (inani elifanele <40%).

5. Ukuqina kodonga lomkhiqizo kuzoba yinani elijwayelekile, futhi okungenani ukuguqulwa okungazelelwe kuzocatshangelwa ukugwema ukubola.

6. Uma ingxenye ebunjiwe yomjovo ifakwe i-electroplated, isikhunta esinyakazayo sidinga nokupholishwa.Izidingo zokupholisha zingeyesibili kuphela kuzidingo zokupholisha isibuko ukuze kuncishiswe ukukhiqizwa kwezinto ezibandayo ngesikhathi sokwenza.

7. Izimbambo nemisele emigodini nasezinkambeni ezingenawo umoya ohlanzekile kufanele kushunyekwe ukuze kugwenywe ukungeneliseki kanye nezimpawu zokuhangula.

8. Okufakiwe, okufakiwe, njll. kuzobekwa futhi kulungiswe ngokuqinile, futhi idiski izohlinzekwa ngezinyathelo zokulwa nokujikeleza.Akuvunyelwe ukupakisha ithusi nensimbi ngaphansi kokufakwayo.Uma i-welding pad iphakeme, ingxenye eshiselwe izoba indawo enkulu yokuxhumana futhi ibe phansi.

Isikhathi sokuthumela: Mar-10-2022